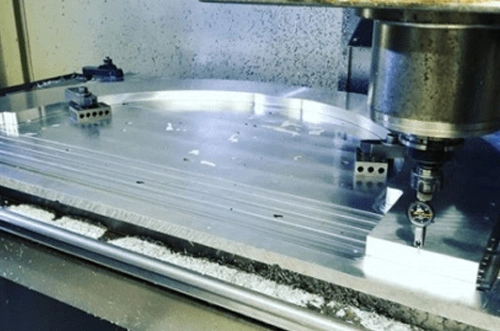

Computer numerical control (CNC) machining provides complex cuts at challenging angles within minutes per item. Programmable software enables the machine to carefully follow the requirements of a digital design and repeat the necessary steps to realize it. CNC machining is perfect for parts with tight tolerances for manufacturing and has a high rate of repeatability from part to part, ensuring precision across all components created in the same production run regardless of production volume.

At Precision Waterjet & Laser, our machining equipment allows us to provide superior quality and value to our partners even on the most complicated projects. Our in-house machinery includes a variety of advanced equipment, including precision CNC machine tools from Haas. Our skilled machinists stay updated with all the latest machining technology and best practices, allowing us to achieve:

- Tolerances of +/- 0.0005” for concentricity, diameter, and straightness

- Tolerances of +/- 0.001” on lengths above 24”

- Milling dimensions up to 64” x 32” x 30”

- Turning dimensions up to 16” length and 23” diameter

- 5-Axis Milling up to 30” x 20” x 20”

See our full gallery for videos & past projects in

CNC Machining.

Gallery Types of CNC Machining

CNC machining refers to a broad range of equipment types that use computer numerical control to guide and automate complex cutting and forming processes. Some of the most common types of CNC machining include:

Drilling

Drilling relies on multi-point drill bits to form cylindrical holes in a workpiece. Using CNC machining equipment provides precision computer-guided control over the drill bit, allowing the formation of highly precise vertical holes. CNC drilling allows the incorporation of more complex drilling processes such as countersinking, counterboring, reaming, and tapping using specialized tooling and workholding solutions, also facilitating the creation of angular holes.

Milling

A reductive machining process, milling uses rotating multi-point cutting tools to remove material from the workpiece in accordance with design specifications. In manual milling operations, operators traditionally feed the workpiece into the milling machine in a direction counter to the rotation of the cutting tools. With CNC equipment, however, the cutting tools can perform precision cuts even while the workpiece rotates in the same direction. The versatility of CNC milling allows capabilities such as:

- Face milling. Face milling is used to make cuts on flat surfaces or to create flat-bottomed cavities within a workpiece.

- Peripheral milling. This milling process cuts deep slots or threads into the workpiece.

Turning

Turning is another reductive machining method that uses a single-point cutting tool (or multiple single-point cutting tools) to cut material away from the workpiece. Turning machines rotate the workpiece rapidly while the cutting tool presses against the surface to remove the material. CNC turning machines, also sometimes referred to as CNC lathes, are most commonly used to create cylindrical parts. CNC turning machines can handle a variety of tasks, such as:

- Boring

- Facing

- Grooving

- Threading

Other CNC Machine Operations

Numerous other machining processes are compatible with CNC technology, such as:

- Broaching

- Sawing

- Grinding

- Honing

- Lapping

Wide Range of Materials

CNC is compatible with an expansive range of raw materials, perfect for a wide variety of applications, including:

- Aluminum

- Brass & copper

- Composites

- Exotic metals/alloys

- Precious metals

- Plastics/polymers

- Stainless steel

- Steel

- Super hard specialty alloys

Industries Served

At Precision Waterjet & Laser, we offer our CNC machining services to create critical parts used in a variety of industries, ranging from heavy equipment parts for industrial applications to complex aerospace components. While we can handle projects in virtually any sector, some of the industries we frequently work with include:

- Aerospace Industry

- Agriculture Industry

- Automotive Industry

- Construction Industry

- Medical Industry

CNC Machining From Precision Waterjet & Laser

At Precision Waterjet & Laser, we use our extensive CNC machining capabilities to fabricate extremely precise parts and components of the highest quality. Our 40,000-square-foot facility houses a broad portfolio of advanced CNC machining equipment, granting our skilled machinists the capability to produce components of nearly any complexity.

We cost-effectively manage singular orders and medium-volume production runs, and rush orders are available upon request for an additional cost. Our manufacturing capabilities extend beyond CNC services into other value-added services, including painting, powder coating, cutting to order, and more. For a complete project quote, please reach out to us.

As an ISO 9001:2015 and AS 9001 certified provider in the manufacturing industry, we can handle any CNC need. To see how we can help with your CNC machining project and get a quote, please contact us.